Maintenance of spindles and core drills

Periodical maintenance of the spindles and core drills prolongs the machines lifespan.

What could damage the spindles?

– If you forget to return the lever in the neutral position and one of the core drill bits remains in the hole – after that if you move a support bar up then the rotor shaft can get bent or even worse the motor feet can break.

– If you bump into the core drill when the glass is relocating.

– If you put too much force onto the spindle when the core drill bit is loose.

– If you forget to treat the spindle and core drill against limescale.

Prevention/ maintenance.

Move the lever in the neutral position after drilling both holes. Lock the lever using a pin.

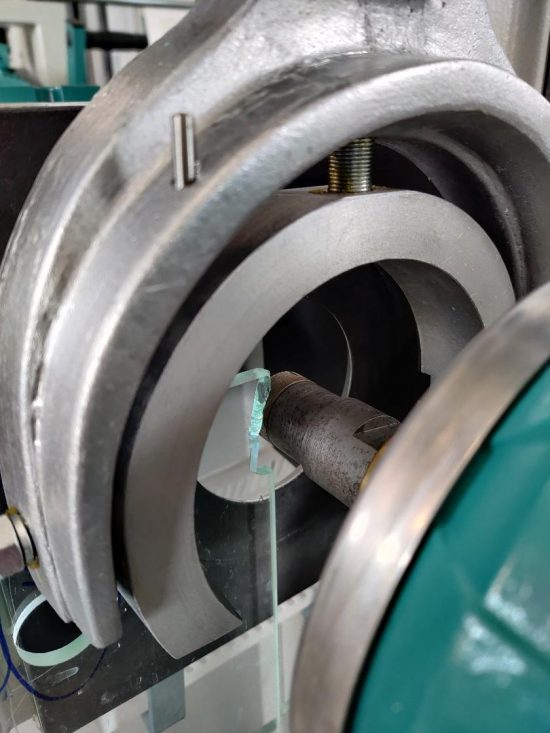

Do not use shock force for tightening the core drill bit. The regular rising of the force is sufficient. The bit cone must be inserted into the spindle cone without any gap present. This will ensure the cone can be tightened correctly.

Do not start the drilling motors when the bits are not sufficiently tight. Loose bits are automatically tightened by shock force when they first touch the glass. The bits are hard to loosen then.

Put some thin grease on the threads, the cone of the spindles and the drill bits. Repeat this process every week.

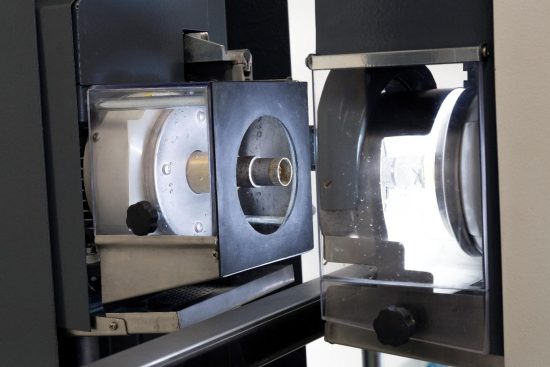

Replace the gasket and spring-loaded sealing in the water housing when the water starts dropping from the indication output. Do not replace the bushing in the motor shaft. Use fine sand paper to polish the head of bushing.

Replace the gaskets and ball bearings when refurbishing the motors.

Spindle failures.

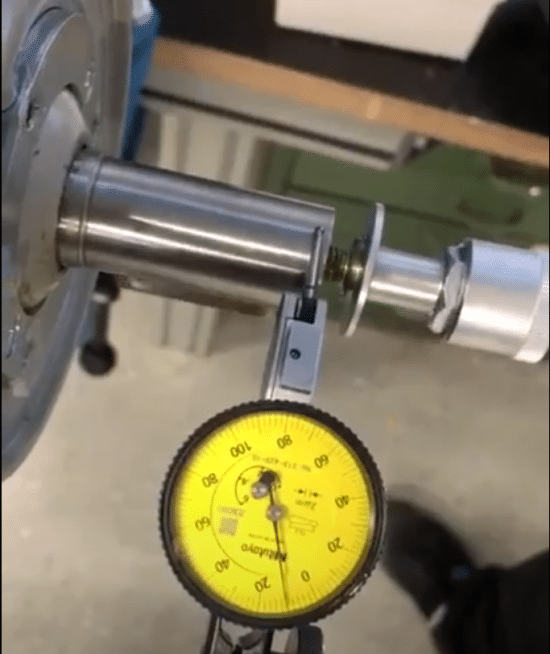

Spindle vibration is present by drilling or motor free runs. The core drill bits wear on the perimeter of the drill bit. Unscrew the core drill bits and look for any deformations and damages. Do the check the possible bending of the rotor shaft.

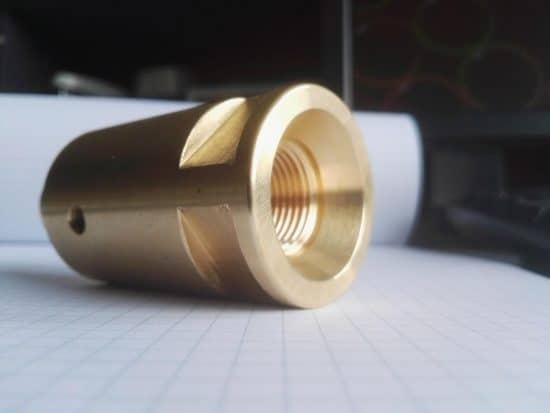

Do the check for damage at the rim of the brass spindle. Remember there should be no gap between the cones.

Check if the cones and threads are clean without any limescale or other elements.

Repair.

Removing limescale and dirt will help prevent any damages. Replace the brass spindle or rotor if there is a lot of damage. In the worst-case scenario, replace whole spindle.

.

Sulak - Glass working machinery

Sulak - Glass working machinery